Surface Treatment

|

|

|

| |

| No dead angle design, world-leading atomization technology; Low solvent consumption, lower VOC |

|

- 15 years of industry technology precipitation

- Automatic spray gun for precision spraying

- Accurately adjust the flow

- Excellent atomization effect and

- Super high transfer efficiency

|

| |

Intelligent Digital Spraying:

|

.png) |

|

| Spraying simulation |

|

|

|

|

| Precision spray control system |

|

|

|

|

| Automatic color change system |

|

|

|

|

| Spraying MES |

|

|

| |

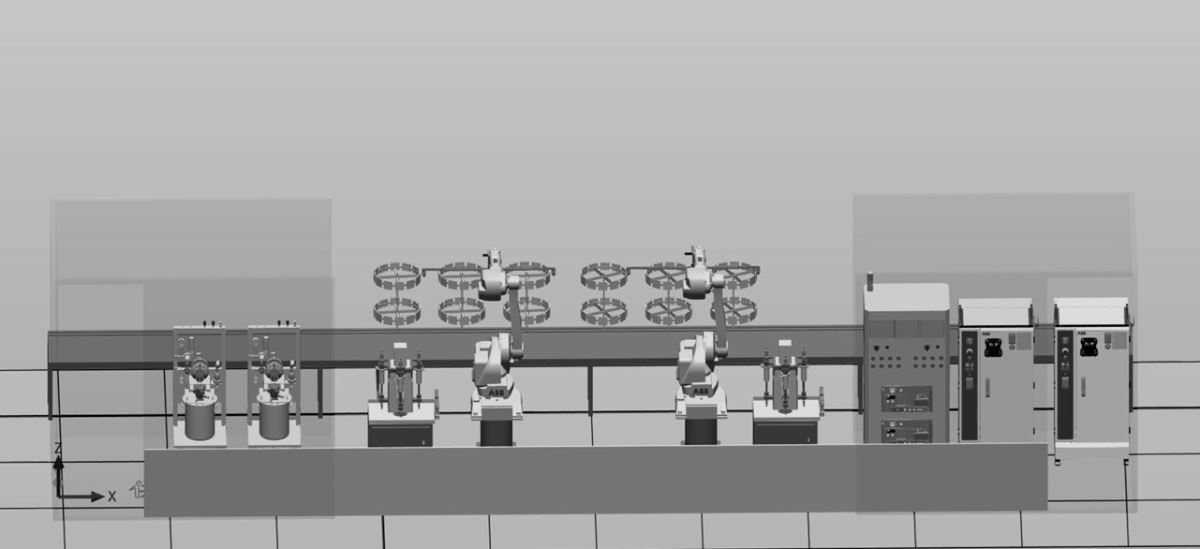

| Core products: YR Shenglong coating line system, YR precision spray control system, spray simulation |

| |

|

|

Advance Conveyor System

|

| This technology originated from Japan. In the Chinese market, through our company's years of R&D and application experience, we integrate this technology into multi-industry, multi-application, and multi-brand robots. |

|

|

|

Product Advantages

|

|

- save space;

- Reduce energy consumption (the cooling and heating capacity of the air conditioner is reduced by more than 1/3);

- Reduce VCO emissions;

- Can achieve fixed point spraying;

|

|

|

|

| |

|

| |

Precision Spray Control System

|

| 6-axis explosion-proof robot, accurate measurement of measuring cylinder Two-color ,1 cleaning automatic color-changing system |

|

|

|

Product Advantages

|

- High-precision measurement: 1cc precise control

- Quick change type/color change: realize flexible production

|

|

|

|

| |

|

|

| Optimize product design through spraying simulation and improve debugging efficiency |

|

|

Spraying Simulation

|

- Precise robot installation and positioning, product spraying range confirmation

- Design and planning of spray booth size, optimize spray booth space and energy consumption

- High-precision simulation program, including coloring effects, can analyze and optimize the most suitable trajectory at the design stage. The program can be directly applied to on-site production, which greatly improves debugging efficiency;

|

|

|

| |

|

| Provide green energy and environmental protection overall solutions |

|

- RTO/RCO Waste gas treatment

- Wastewater treatment

- Cleanroom "turnkey" project

- 1000 level to 100, 000 level cleanroom project

|

| |

|

|

| 1,000-level ordinary air-conditioning workshop |

|

|

|

|

|

| 10,000-level purification aseptic air-conditioning workshop |

|

|

|

|

|

|

|

| |

|

|

| 100,000-level constant temperature and humidity workshop |

|

|

|

|

|

| 100,000-level medical constant temperature clean room |

|

|

|

|

|

| Catalysis + activated carbon adsorption |

|

|

|

|

|

| Wastewater treatment pipeline |

|

|

|

|

|

|